Sealing problems and characteristics of flat welded flange

Release Time:

Mar 18,2024

The sealing problem of flat welded flange has always been a hot issue related to the production cost or economic benefit of enterprises, so the sealing principle of flat welded flange has been improved and perfected.

The sealing problem of flat welded flange has always been a hot issue related to the production cost or economic benefit of enterprises, so the sealing principle of flat welded flange has been improved and perfected. However, the main design disadvantage of flat welded flanges is that they are not guaranteed to be leak-free. This is a design flaw: the connection is dynamic, and periodic loads, such as thermal expansion and fluctuating loads, can cause the flanges to move against each other, affecting the function of the flanges, thereby compromising the integrity of the flanges and ultimately leading to leakage.

The sealing problem of flat welded flange has always been a hot issue related to the production cost or economic benefit of enterprises, so the sealing principle of flat welded flange has been improved and perfected. However, the main design disadvantage of flat welded flanges is that they are not guaranteed to be leak-free. This is a design flaw: the connection is dynamic, and periodic loads, such as thermal expansion and fluctuating loads, can cause the flanges to move against each other, affecting the function of the flanges, thereby compromising the integrity of the flanges and ultimately leading to leakage.

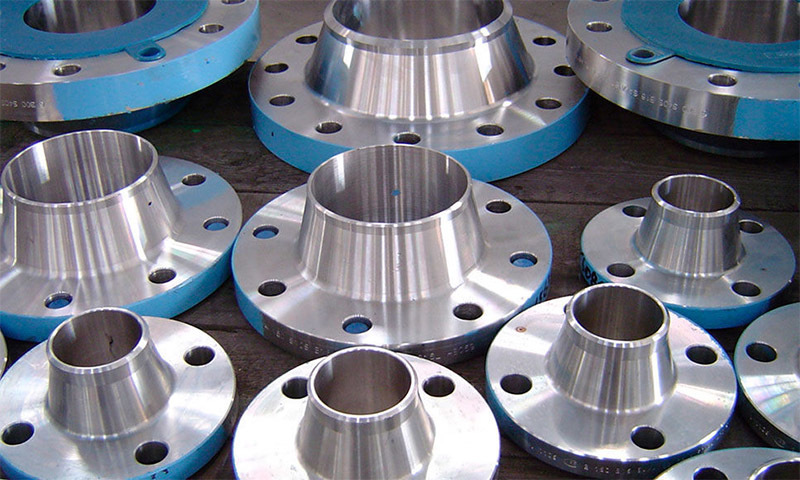

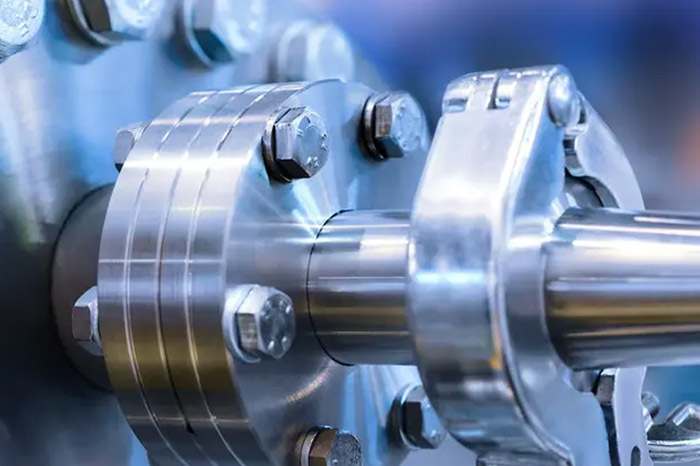

The sealing principle of the flat welding flange: the two sealing surfaces of the bolt squeeze the flange gasket to form a seal, but this will also lead to seal damage. In order to maintain the seal, you have to maintain a huge bolt force, and in order to do this, you have to make the bolt bigger. The larger bolt matches the larger nut, which means that a larger bolt diameter is needed to create the conditions to tighten the nut. However, the larger the diameter of the bolt, the flange will be bent, and the only way is to increase the wall thickness of the flange part. The entire installation will require enormous size and weight, which is a particular problem in offshore environments, where weight is always a major concern. And, fundamentally, the flat welded flange is an ineffective seal that requires 50% of the bolt load to be used to squeeze the gasket, while only 50% of the load is used to maintain the pressure. Flat welded flange is often used in the medium temperature and pressure are not high and the medium corrosive situation. When the medium is corrosive. Rare integral flanges are flat welded flanges and butt welded flanges. Flanged pipe fittings are pipe fittings with flanges (flanges or joints). It can be made of casting, flat welded flange is mainly the part that connects the pipe with the pipe. According to the type of structure. It can also be threaded or welded. The flange connection is composed of a pair of flanges, a gasket and a number of bolts and nuts.

Features of flat welded flange:

The flat welded flange not only saves space and reduces weight, but more importantly, ensures that the joint part does not leak and has good sealing performance. The reduction in the size of the compact flange is due to the reduction in the diameter of the seal, which will reduce the cross section of the sealing surface. Secondly, the flange gasket has been replaced by a sealing ring to ensure that the sealing face matches the sealing surface. In this way, very little pressure is required to compact the cover. With the reduction of the required pressure, the size and number of bolts can be reduced accordingly, so the final design of a small volume and light weight (than the traditional flange weight reduction of 70% to 80%) of the new product. Therefore, the flat welded flange is a high-quality flange product, which reduces the quality and space, and plays an important role in industrial use. However, the main design disadvantage of flat welded flanges is that they cannot be guaranteed to be leak-free. This is the design of the deficiency: the connection is dynamic, and such as thermal expansion and fluctuating periodic loads can cause movement between the flanges, affecting the function of the flange, so that the integrity of the flange is damaged, and eventually lead to leakage. No product can be without defects, but try to control the insufficiency of the product to a minimum, so the company tries to improve the performance of the product in the production of flat welding flange, so that it can play a maximum role.

Keywords:

More information