What are the advantages of flat welded flange?

Release Time:

Jan 09,2020

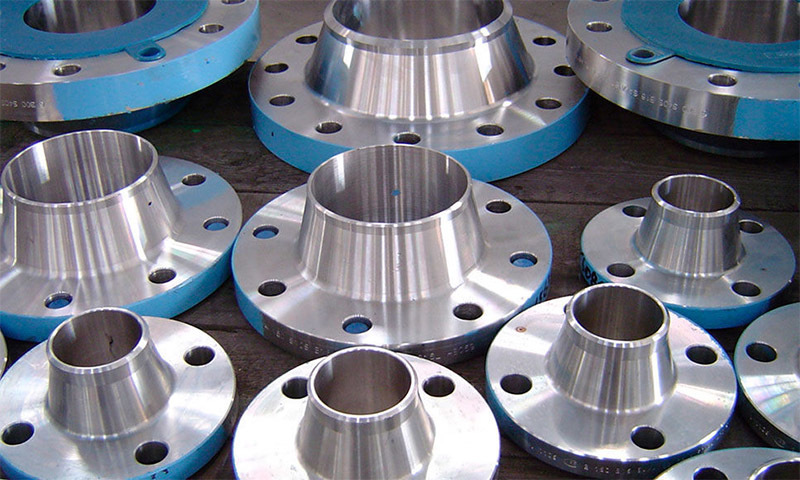

Flat welded flange (HG20593,GB/T9119,JB/T81): convenient materials, simple manufacturing, low cost, widely used;

Flat welded flange (HG20593,GB/T9119,JB/T81): convenient materials, simple manufacturing, low cost, widely used; However, the rigidity is poor, so it can not be used for supply and demand, flammable, explosive and high vacuum requirements of the chemical process piping system and height, extremely hazardous occasions.

Flat welded flange (HG20593,GB/T9119,JB/T81): convenient materials, simple manufacturing, low cost, widely used; However, the rigidity is poor, so it can not be used for supply and demand, flammable, explosive and high vacuum requirements of the chemical process piping system and height, extremely hazardous occasions. The sealing surface type has a plane and a protruding surface.

The flange applies to the standard Chemical industry HG/T20592-2009, GB/T9119-2010, machine standard JB/T81-94.

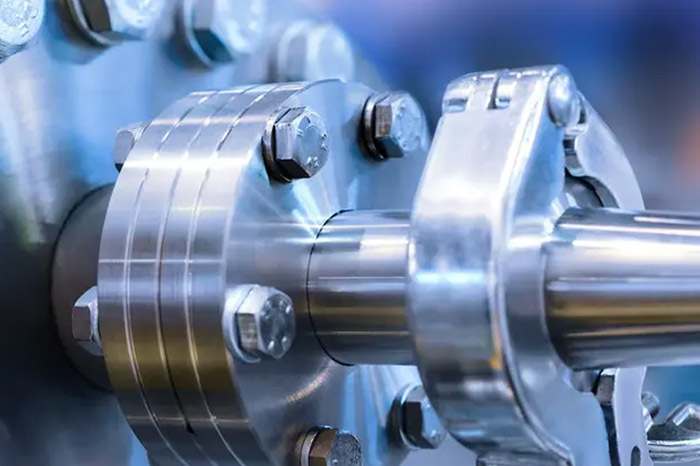

The main shape size and connection size reference flange standard, flange flange (flange) connection is the two pipes, pipe fittings or equipment, first fixed in a flange, between the two flanges, plus flange pad, bolted together to complete the connection. Some pipe fittings and equipment have their own flanges, which are also flange connections. Flange connection is an important connection mode in pipeline construction. The flange connection is easy to use and can withstand greater pressure.

Flat welded flange with neck attached to tube end. It is mainly a part that connects the pipe to the pipe. There are holes in the flange, and bolts can be worn to make the two flanges tightly connected, and the flange is sealed with a liner. Flat welded flange with neck is also a flat welded flange, because it has a short neck, which improves the strength of the flange and improves the bearing force of the flange. So it can be used on higher pressure pipes. Flanged pipe fittings are pipe fittings with flanges (flanges or joints). It can be cast, or it can be threaded or welded. The flange connection is composed of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the sealing surface of the two flanges, and after tightening the nut, the specific pressure on the surface of the gasket will be deformed after reaching a certain value, and the uneven part of the sealing surface will be filled to make the connection tight and not leak. A flange connection is a detachable connection. According to the connected parts can be divided into container flange and pipe flange. According to the structure type, there are integral flange, looping flange and threaded flange. Common integral flanges are flat welded flanges and butt welded flanges.

Keywords:

More information