Introduction of biphase steel flanges and their chemical composition

Release Time:

Mar 18,2024

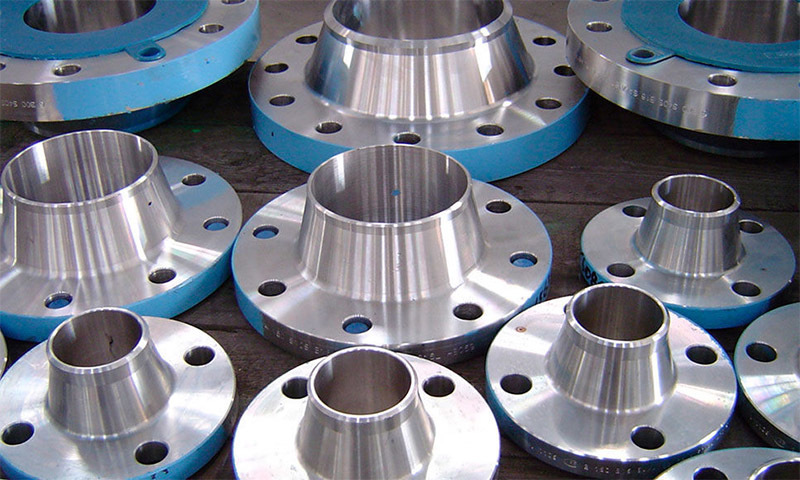

Double phase steel flange, as the name suggests, is a flange produced by the raw material of double phase steel bar, steel ingot or plate, referred to as double phase steel flange, flange is also called flange or flange.

Double phase steel flange, as the name suggests, is a flange produced by the raw material of double phase steel bar, steel ingot or plate, referred to as double phase steel flange, flange is also called flange or flange. It is the part that connects the pipe to the pipe. Connect to tube end.

Double phase steel flange, as the name suggests, is a flange produced by the raw material of double phase steel bar, steel ingot or plate, referred to as double phase steel flange, flange is also called flange or flange. It is the part that connects the pipe to the pipe. Connect to tube end. There are holes in the flange, and bolts can be worn to make the two flanges tightly connected. The flange is sealed with a gasket. The flange connection is composed of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the sealing surface of the two flanges, and after tightening the nut, the specific pressure on the surface of the gasket will be deformed after reaching a certain value, and the uneven part of the sealing surface will be filled to make the connection tight and not leak. Some pipe fittings and equipment have their own flanges, which are also flange connections. Flange connection is an important connection mode in pipeline construction.

Dual-phase steel flange using dual-phase steel as raw materials for production, the so-called dual-phase stainless steel is in its solid solution structure of about half of the ferrite phase and austenite phase, the general amount of small phase content also needs to reach 30%. In the case of low C, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain Mo, Cu, Nb, Ti, N and other alloying elements. This kind of steel has the characteristics of austenitic and ferritic stainless steel, compared with ferritic, higher plasticity, toughness, no room temperature brittleness, intergranular corrosion resistance and welding performance are significantly improved, while also maintaining the ferritic stainless steel 475℃ brittleness and high thermal conductivity, with superplasticity and other characteristics. Compared with austenitic stainless steel, it has higher strength and higher resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting resistance and is also a nickel-free stainless steel.

Commonly used biphase steel materials Usually produced by flange manufacturers are the famous super biphase steel S32205 S31803 S32750 S32760 and so on.

Two-phase steel S31803 commonly known as F51 Its chemical composition is Carbon ≤0.030 manganese ≤2.00 Silicon ≤1.00 Phosphorus ≤0.030 sulfur ≤0.020 Chromium 21.0~23.0 Nickel 4.5~6.5 Molybdenum 2.5~3.5 iron allowance other N0.08 ~ 0.2

The chemical composition of S31803 and the famous duplex steel 2205 chemical material composition is similar, the price difference is not high. Therefore, 2205 duplex steel is generally used to replace S31803 duplex steel, but S31803 duplex steel can not replace 2205 duplex steel. Duplex steel 2205 is also called S32205 commonly known as F60 corresponding to the domestic brand: 00Cr22Ni5Mo3N Its chemical composition is Carbon ≤0.030 Manganese ≤2.00 Silicon ≤1.00 Phosphorus ≤0.030 sulfur ≤0.020 Chromium 22.0 ~ 23.0 Nickel 4.5 ~ 6.5 Molybdenum 3.0 ~ 3.5 Iron allowance Other N0.14 ~ 0.2

Duplex steel S32750 also known as 2507 commonly known as F53 00Cr25Ni7Mo4N Its chemical composition is carbon ≤0.030 manganese ≤1.20 silicon ≤0.80 phosphorus ≤0.035 sulfur 0.020 chromium 24.0 ~ 26.0 Nickel 6.0 ~ 8.0 molybdenum 3.0 ~ 5.0 Copper ≤0.50 Iron allowance other N0.24 ~ 0.2

Two-phase steel S32760 commonly known as F55 its chemical composition is carbon ≤0.030 manganese ≤1.20 Silicon ≤0.80 phosphorus ≤0.035 sulfur ≤0.020 Chromium 24.0 ~ 26.0 Nickel 6.0 ~ 8.0 molybdenum 3.0 ~ 4.0 copper 0.50 ~ 1.0 iron surplus Other N0.20~0.30 W 0.50 ~ 1.

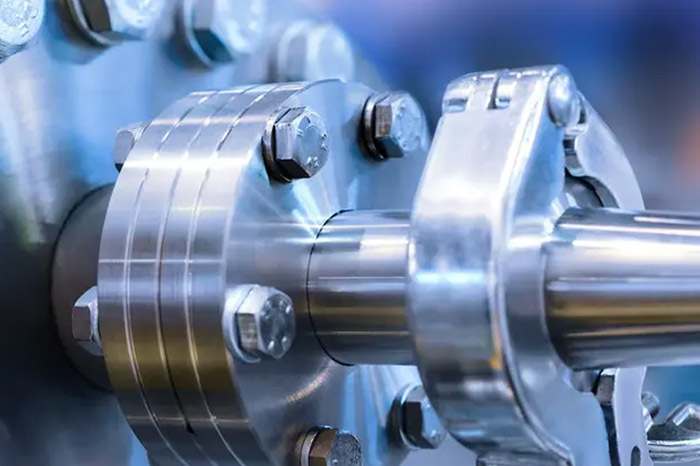

The double-phase steel flange expansion joint is suitable for connecting both sides with the flange, adjusting the connection length between the two ends of the product and the flange during installation, tightening the gland bolt evenly diagonally with the neck flange, and then adjusting the limit nut, so that the pipeline can be freely expanded within the expansion range, locking the expansion amount, and ensuring the safe operation of the pipeline.

Suitable for both sides of the pipe connected with flanges, adjust the installation length of both ends of the product and the flange during installation, diagonally tighten the gland bolt evenly, so that it becomes a whole, and has a certain amount of displacement, convenient installation and maintenance, according to the site size adjustment. High-performance duplex steel flanges can be widely used in a variety of sewage treatment pipelines, can carry out deep-sea operations, seawater desalination and paper industry equipment above, in the offshore oil platform is used as desalination equipment.

Due to these advantages of duplex steel flanges. It is widely used in various sewage treatment pipelines, deep sea industry, seawater desalination, paper industry equipment, food industry processing equipment, offshore oil platform (heat exchanger pipe, water treatment and water supply system) desalination (desalination) equipment, oil field pipelines and equipment, all kinds of acid and alkali environment, due to good wear resistance and corrosion resistance. The use of help life is more than the general stainless steel four to five years, such as in the seawater pipeline, the use of dual-phase steel flange, due to long life, can greatly reduce the cost of product replacement, labor costs, relatively high cost performance.

Keywords:

More information